DTF (Direct to Fabric) Transfers Ready To Press are transforming T-shirt branding by offering unparalleled versatility, quality, and durability. This technology streamlines printing, eliminating traditional setup times, and maintaining exceptional print quality on complex artwork transfers. By implementing DTF in your production process, businesses can enhance efficiency, meet tight deadlines, and ensure vibrant designs that last through multiple washings, standing out in the competitive apparel market.

“Unleash the potential of your t-shirt brand with DTF Transfers Ready to Press – a game-changer in the apparel industry. This comprehensive guide explores the world of Direct to Fabric (DTF) transfers, offering a revolutionary approach to printing on t-shirts. From understanding the technology to uncovering its numerous advantages, we delve into how ready-to-press DTF transfers can enhance efficiency and quality. Get ready to revolutionize your production process with this cutting-edge technique.”

- Understanding DTF Transfers: A Comprehensive Guide for T-Shirt Brands

- Benefits of Ready-to-Press DTF Transfers: Efficiency and Quality Unlocked

- Best Practices for Implementing DTF Transfers in Your T-Shirt Production Process

Understanding DTF Transfers: A Comprehensive Guide for T-Shirt Brands

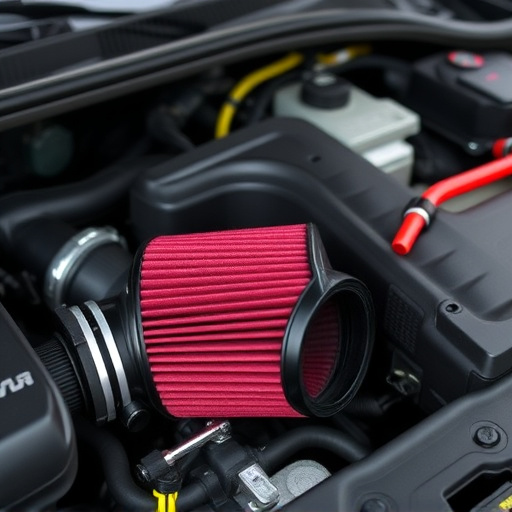

DTF (Direct to Fabric) Transfers are a cutting-edge technology revolutionizing the T-shirt branding industry. This print method offers unparalleled versatility and quality, making it an attractive option for businesses looking to create unique and durable designs on apparel. With DTF transfers, brands can effortlessly incorporate intricate graphics, photos, and text directly onto fabric, ensuring a crisp and long-lasting finish.

For T-shirt brands, understanding DTF Transfers goes beyond the technical specifications. It involves grasping how this process enhances product customization, speeds up production time, and increases customer satisfaction due to the superior quality of printed shirts. Moreover, DTF printing services prioritize durability, guaranteeing that designs remain vibrant and intact even after repeated washings, ensuring the longevity of the final product.

Benefits of Ready-to-Press DTF Transfers: Efficiency and Quality Unlocked

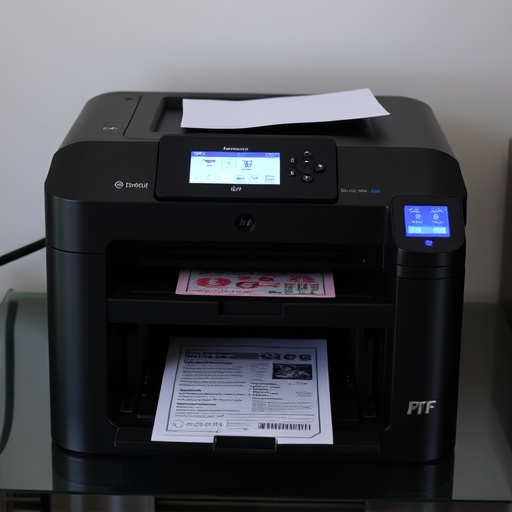

The advent of DTF Transfers Ready to Press has revolutionized the t-shirt branding industry, offering a seamless and efficient solution for businesses seeking high-quality custom designs. This cutting-edge technology streamlines the printing process, eliminating the need for costly setup times and intricate plate preparations commonly associated with traditional printing methods. With DTF (Direct to Garment) transfers, brands can swiftly transform their creative visions into tangible products, catering to the fast-paced demands of modern retail.

One of the standout advantages of Ready-to-Press DTF Transfers lies in their ability to maintain exceptional print quality across various garments and designs. The direct application of artwork onto transfer paper ensures precise color reproduction and vibrant, long-lasting images. This precision is particularly beneficial for intricate dtf design transfers and complex dtf artwork transfers, allowing brands to deliver visually stunning t-shirts that captivate customers. Moreover, the efficiency gained through this process enables businesses to meet tight deadlines, ensuring they stay competitive in a dynamic market where speed and quality are paramount.

Best Practices for Implementing DTF Transfers in Your T-Shirt Production Process

Implementing Direct-to-Fabric (DTF) transfers in your T-shirt production process can significantly streamline operations and enhance product quality. Begin by uploading your own gang sheet designed specifically for DTF printing. This allows for precise control over design placement, ensuring alignment and accuracy throughout the transfer process. Choose high-quality DTF transfers to guarantee vibrant colors and long-lasting durability on various fabric types.

Best practices dictate preparation of your designs in high-resolution formats, adhering to recommended file specifications. Calibrate your equipment for optimal temperature and pressure settings, ensuring consistent application of heat during the transfer process. Regularly maintain and clean your machinery to prevent clogs and ensure smooth operation. Lastly, select appropriate fabric types compatible with DTF transfers to maximize adhesion and final product quality.

DTF Transfers Ready to Press are revolutionizing the t-shirt branding industry by offering a streamlined, efficient solution for high-quality printing. By adopting this technology, brands can significantly enhance their production process, ensuring fast turnaround times and consistently superior results. With the right implementation strategies outlined in this guide, t-shirt manufacturers can unlock new levels of productivity and creativity, positioning themselves as industry leaders.